The development and manufacture of complex mechanical components require quality assurance, precision, and process control at every stage of a project. That's why we continuously invest in:

- Thorough preparations and digital integration in our ERP system.

- A quality department that inspects all incoming and outgoing parts.

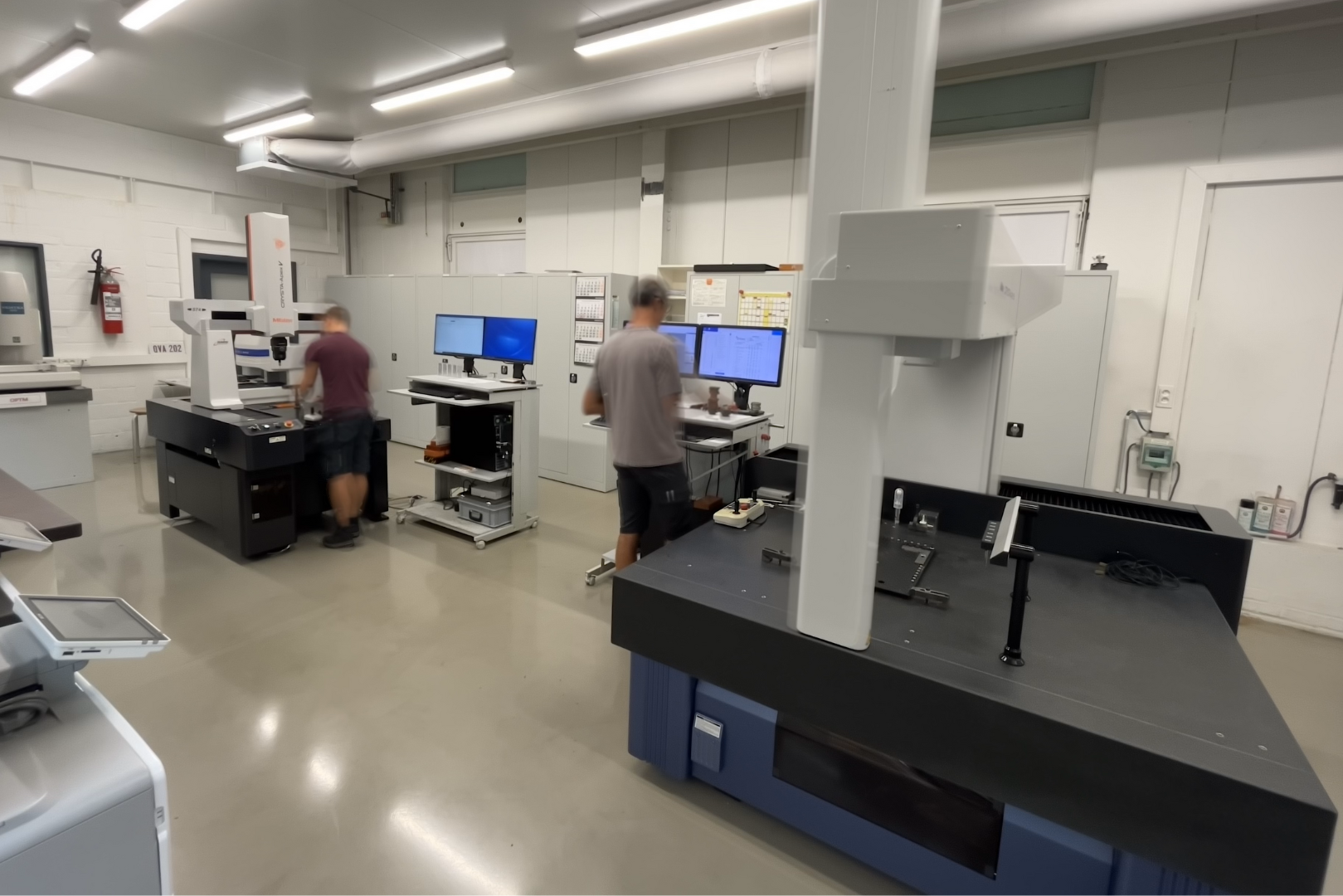

- A climate-controlled metrology laboratory with:

- Two CMMs with an accuracy of 1.7µm

- An optical measuring machine with an accuracy of 3µm

- Numerous other measuring instruments such as a vertical Trimos measuring instrument, a roughness meter, a hardness tester, and a profile projector.

- Micat software with PMI (Product Manufacturing Information) for reading 3D files and programming measurement cycles.

- Provision of measurement reports and material certificates.

- Annual calibration and maintenance of all measuring instruments and equipment.

- Annual quality audit according to the EN15085-2 standard (Quality Manual).

This commitment to quality ensures that we consistently deliver high-quality products. This eliminates the need for incoming inspection by our customers.

CMM

Our Coordinate Measuring Machines:

Mitutoyo Crysta-Apex V:

Precision: 1.7µm

Max. dimensions: 500mm x 700mm x 400mm

Max. load 180 kg

'Touch trigger' feature, to acces hard-to-reach ereas

Mitutoyo Crysta-Apex S:

Precision: 1.7µm

Max. dimensions: 900mm x 1000mm x 600mm

Max. load 1200 kg, accessed by a overhead crane

'Scanning probe' feature measures critical surfaces by continuously streaming. This is particularly useful for cam contours we design, calculatea and produce as it provides measurement data for the entire contour.

VMM

Our Visual Measurement Machine:

Mitutoyo Quick Vision Active:

Precision: 3µm

Max. dimensions: 250mm x 200mm x 150mm

Max. load: 10kg

Ideal for rapid serial measurements, not only of dimensions but also for detecting burrs and surface defects.

High-end precision parts

High-end precision parts